Dry Gas Mechanical Seal

Dry Gas Mechanical Seal

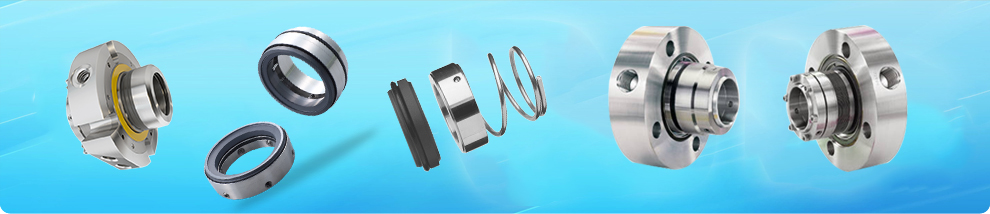

Dry gas seals are available in a variety of configurations, but the "tandem" style seal is typically applied in process gas service. Tandem seals consist of a primary seal and a secondary seal, contained within a single cartridge. During normal operation, the primary seal absorbs the total pressure drop to a vent system, and the secondary seal acts as a backup should the primary seal fail.

The use of these seals in centrifugal compressors has increased significantly in the last two decades because they eliminate contamination and do not use lubricating oil. Non-contacting dry gas seals are often used on compressors for pipelines, off-shore applications, oil refineries, petrochemical and gas processing plants.

Types of the Dry Gas Mechanical Seal:

- 1. single seal

- 2. Tandem Seal: used in the petroleum industry and Tandem Seal with intermediate labyrinth

- 3. Double Opposed seal : Used when the processed gas is abrasive (like hydrogen) and lower pressure designs.

Dry Gas Mechnical Seal Product Manufacturing:

- Tandem seal, with additional labyrinth seal or without it

- Double seal, with additional labyrinth seal or without it

- Triple seal for extra clean processes (combination of tandem and double seals so that nitrogen does not get into the process, but the process

- gas does not get into the bearing / shop atmosphere as well)

- Rigid radial and thrust bearings (useful when upgrading from oil mechanical seals)

- Control panels, Emerson (Fisher/Rosemount) based (useful when upgrading from oil mechanical seals or for supply to OEM).